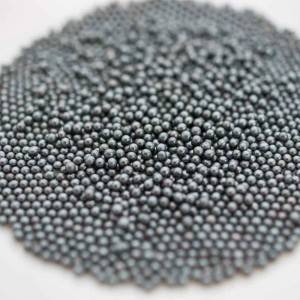

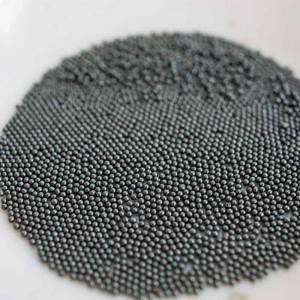

Sethunya sa tšepe se pota-potiloeng ka Carbon e tlase

Mohlala/Boholo:S110-S930/Φ0.3mm-2.8mm

Lintlha tsa Sehlahisoa:

Lits'oants'o tsa tšepe tse tlase tsa khabone li na le khabone e nyane, phosphorus le sebabole ho feta lithunya tse phahameng tsa carbon steel.Ka hona, sebopeho sa ka hare sa micro carbon shots se bonolo haholo.Lits'oants'o tsa tšepe tse tlase tsa khabone li bonolo ha li bapisoa le lithunya tse phahameng tsa carbon steel.Sena se fella ka 20 - 40% ea nako e telele ea bophelo ba ho senya.

Litlhaloso tsa Bohlokoa:

| MORERO | TS'ELISO | TEKO MOKHOA | |||

| MOTS'EOA CHEMEKE | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| MOEKETSI | Homogeneous Martensite kapa Bainite | GB/T 19816.5-2005 | |||

| Botenya | ≥7.0-10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| KAKELETSO | Sekoti sa moea <10%.Kopanya.Sekhutlo se bohale.Deformity Rate< 10% | E bonoang | |||

| THATA | HV:390-530(HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Mehato ea Ts'ebetso:

Sekhechana → Kgetha & Ho Seha → Ho qhibiliha → Hloekisa(Decarbonize) → Ho futhumatsa → Ho omisa → Ho omisa → Scalper Screening → Ho phefumoloha le ho butsoela ho ntša lesoba la moea → Ho tima la pele → Ho omisa → Ho halefa → Ho halefa ha bobeli → Ho Pholisa → Ho Hlahlobisisa Hantle → Ho paka le ho Boloka

Lisebelisoa:

Libaka tse tloaelehileng tsa ts'ebeliso: pele ho phekolo ea tšepe kapa tšepe ea tšepe pele ho penta, ho theoha le ho tlosoa ha mafome, ho senya.

Melemo:

① E loketse ho sebelisoa ho fana ka tšepe e hloekileng, e bentšitsoeng.

② Lits'oants'o tsa tšepe tse tlase tsa khabone li sebelisoa ka har'a turbine le lits'ebetsong tse hatelitsoeng tsa moea.Lits'oants'o tsa tšepe tse tlase tsa khabone li netefatsa hore mahare a tlase a turbine a apareloa.

③ Nako ea bophelo ea lithunya tsa tšepe e tlase e ka ba bolelele ba 30% ho feta lithunya tse tloaelehileng tsa tšepe e phahameng ea carbon.

④ Ts'ebetso ea ho phatloha ha sethunya e hlahisa lerōle le lenyane, e leng se fellang ka litšenyehelo tse tlase tsa tlhokomelo ea sistimi ea filtration.

Ke Hobane'ng ha Khabone e Tlase?

Lithunya tse tlase tsa khabone le tšepe e phahameng ea manganese li na le matla a ho monya a matla, litšusumetso li ajoa ka mokhoa o ts'oanang nakong ea thunya.

Nakong ea ts'ebetso ea ho phatloha ha lithunya, tšepe e tlaase ea carbon e eboloa ka likarolo tse tšesaane tse tšoanang le likarolo tsa eiee bakeng sa karolo ea 80 lekholong ea bophelo ba tsona ka lebaka la ho khathala, 'me li robeha feela likotoana tse nyenyane ka lebaka la mokhathala oa thepa.Khoholeho ea mochini le lehare le eona e fokotsehile haholo kaha li arotsoe ka likarolo tse nyane le tse nyane.

Likaroloana tsa tšepe tse phahameng tsa carbon steel leha ho le joalo li robehile likotoana tse kholo le tse mahlakore a mabeli ka nako e khuts'oane ka lebaka la sebopeho sa crack se entsoeng nakong ea tlhahiso.Ka tšobotsi ena, mochini o baka litšenyehelo tse eketsehileng ho lisebelisoa tsa turbine le li-filters.